As cities and industries face the challenge of aging underground infrastructure, trenchless technology continues to deliver smarter, more sustainable solutions. One of the most reliable options is cementitious pipe lining. It’s a proven, eco-friendly method that restores deteriorating pipes without the cost or disruption of full replacement.

At Advanced Pipe Repair, we use cementitious materials to rebuild structural integrity from the inside out. Whether the problem is corrosion, infiltration, or surface degradation, this technique provides a durable and environmentally responsible way to extend pipeline life for decades.

Understanding Cementitious Pipe Lining

Cementitious linings are specialized mortar-based coatings engineered to protect and strengthen deteriorating pipes. They are composed of high-performance cement, graded aggregates, chemical admixtures, and corrosion inhibitors that form a dense, impermeable barrier once cured.

Unlike basic cement or grout, modern cementitious systems are fiber-reinforced and polymer-modified, allowing them to adhere to metal, concrete, clay, or brick substrates. The result is a seamless, structural layer that bonds directly to the host pipe’s interior surface. It essentially is rebuilding the pipe from within.

These linings can range from thin protective coatings (1/8 inch) to thick structural rebuilds (1 inch or more), depending on the condition and diameter of the host pipe.

How the Application Process Works

Cementitious pipe lining is applied using trenchless methods that minimize surface disruption and downtime. The process typically follows these key stages:

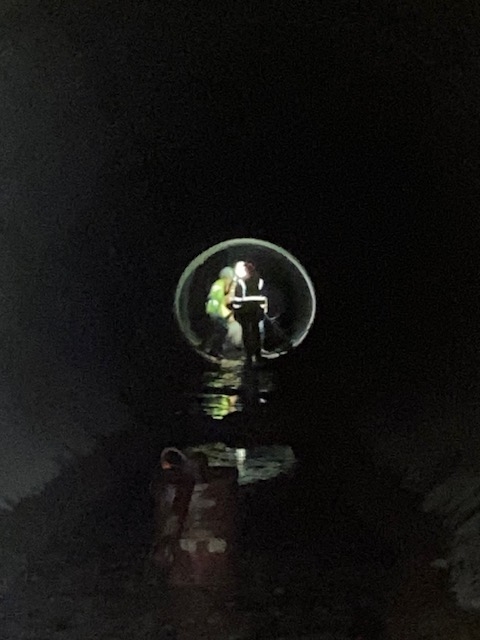

- Cleaning and Surface Preparation: Before application, the pipeline is inspected using CCTV technology and thoroughly cleaned with high-pressure hydro-jetting. Removing scale, sediment, and corrosion ensures the lining will bond effectively.

- Lining Application: Depending on the pipe’s diameter and access points, technicians apply the cementitious material using one of several techniques. Each pass builds up a uniform coating that restores wall thickness and structural strength.

- Curing and Final Inspection: Once application is complete, the lining cures using the method of choice. Curing times vary from 24 to 72 hours depending on thickness and environmental conditions. After curing, we inspect the system and test for adhesion.

The result is a strong, corrosion-resistant interior surface that protects the host structure and restores flow efficiency.

Why Choose Cementitious Linings for Pipeline Restoration

Cementitious lining has become a preferred choice for municipalities and industrial clients looking to balance performance with sustainability. Some of the key advantages include:

Corrosion and Abrasion Resistance

The dense, alkaline surface of cementitious materials resists both chemical attack and abrasion, making them ideal for stormwater and wastewater environments. Additives such as calcium aluminate or microsilica further enhance acid resistance.

Environmentally Friendly and Sustainable

Cementitious linings are low-VOC, non-toxic, and recyclable, using primarily natural materials. Their long service life reduces the need for frequent repairs, lowering overall environmental impact. Additionally, the trenchless application process minimizes excavation, fuel use, and material waste.

NSF/ANSI Compliance

Many modern cementitious formulations meet NSF/ANSI Standard 61 for potable water systems, ensuring they are safe for use in drinking water infrastructure. This makes them a viable option for municipalities working under strict regulatory guidelines.

Structural Reinforcement

Beyond simple coating, cementitious liners provide genuine structural enhancement. In many cases, the lining restores or even exceeds the pipe’s original load-bearing capacity.

How Cementitious Linings Compare to Epoxy and Polymer Systems

Each lining method has its own strengths. The best choice depends on the pipe material, diameter, and environmental conditions.

| Feature | Cementitious Lining | Epoxy Lining | Polymer/CIPP Systems |

|---|---|---|---|

| Material Base | Mineral (cement and aggregate) | Synthetic resin | Resin-saturated liner |

| Structural Strength | High (rebuilds wall thickness) | Moderate | Very high (pipe-within-pipe) |

| Corrosion Resistance | Excellent (especially with additives) | Excellent | Excellent |

| Environmental Impact | Low — natural and recyclable materials | Moderate | Higher resin usage |

| Temperature Tolerance | High | Moderate | Moderate |

| NSF/ANSI 61 Compliance | Available | Common | Limited |

| Best Use | Concrete, CMP, or brick structures | Metal or smooth interior pipes | Long runs or structural replacement |

In short, cementitious linings excel for large, deteriorating pipes where a thick, structural rebuild is necessary. It offers a quick and effective solution without the full installation of a CIPP liner or any digging.

Where Cementitious Lining Performs Best

Because of its strength and versatility, cementitious pipe lining serves a broad range of industries and pipe materials:

- Municipal Infrastructure

- Industrial Facilities

- Power Generation Plants

- Water Utilities

- Transportation and DOT Projects

Its adaptability makes it one of the most flexible trenchless repair systems available today.

Real-World Results: Proven Performance Over Time

Cementitious lining has been used successfully in the U.S. and Canada for decades. Municipalities continue to rely on it because of its long lifespan and consistent performance.

In one Alberta municipality, Advanced Pipe Repair restored a 72-inch corrugated metal stormwater line that had extensive rusting. Using a high-strength calcium aluminate cementitious liner put in place by spin-casting, the structure was ready in just two days.

Post-project inspections showed:

- 100% joint sealing with no visible infiltration.

- Surface strength exceeding 7,000 psi.

- Improved hydraulic flow due to the smooth, uniform interior finish.

Ten years later, follow-up inspections confirmed the lining remained intact, showing minimal wear even under heavy seasonal flows. Now, that is clear evidence of long-term durability.

Cementitious Pipe Lining: A Sustainable Path Forward

As infrastructure systems age and budgets tighten, cementitious pipe lining offers an ideal balance of performance, cost efficiency, and sustainability. It eliminates the need for excavation, reduces carbon emissions, and provides decades of protection against corrosion and infiltration.

Advanced Pipe Repair can engineer a custom solution using cementitious technology specific to your needs. Contact us today.