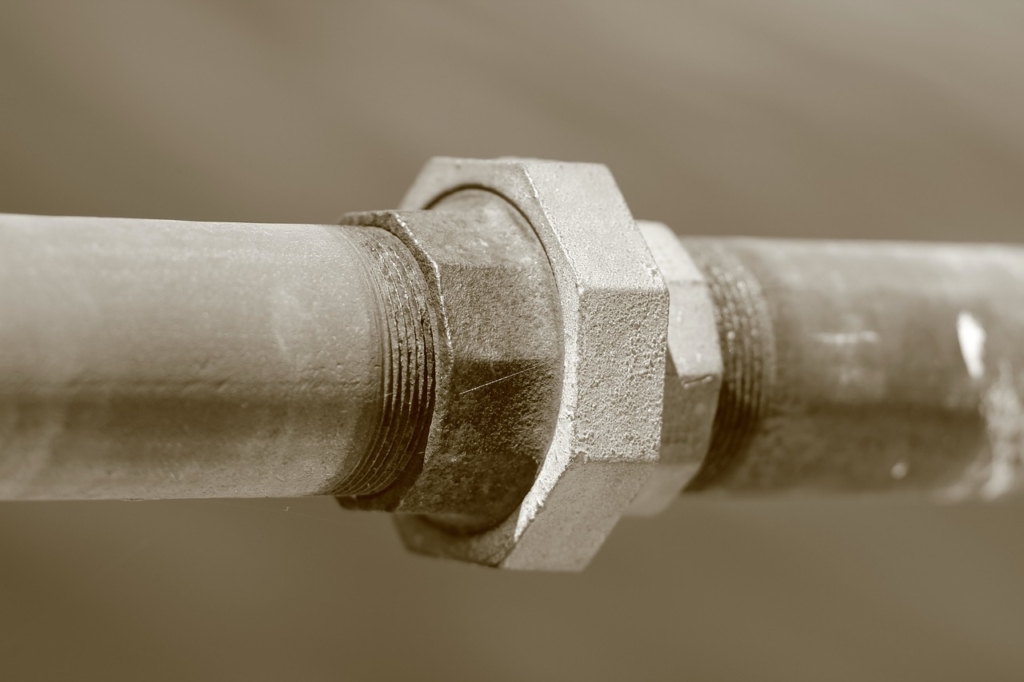

A construction manager for commercial pipe systems should have access to convenient solutions. For instance, any commercial, industrial, or municipal sewer systems can experience burst pipes. This can lead to several complications.

Often, this occurs in hard-to-reach locations. In order to access these pipes for repair, one must spend money to uncover them. This is especially costly if the pipes are beneath a foundation. Not only does this apply to financial concerns, but it also applies to time management, because repairs don’t always go as planned.

For Dallas-located systems, one solution is to partner with Advanced Pipe Repair (APR). Our cured-in-place-pipe (CIPP) rehabilitation methods can repair most existing pipelines. Here’s a guide to a few benefits that a construction manager can experience from teaming up with APR.

No Excavations Needed with CIPP

As a trenchless rehabilitation method, CIPP helps to stop costly excavations from being mandatory procedures. Construction managers can benefit greatly from using such methods correctly. When it comes to repairs, existing pipelines can become structurally unsound if mistakes happen. One thing is for certain: leaks or damages are the last thing you want when sewer, gas, and chemical pipelines are involved.

Besides, these elements can be hazardous to the public. With CIPP, a repair job requires little to no excavation. In fact, this “trenchless technology” allows repairs to occur in a less-disruptive way. APR usually performs CIPP from an upstream manhole or access point.

Basically, this means a liner from a downstream access point can be installed, upstream to a blind end. While it’s complicated, CIPP contractors can use this to properly do the job in an affordable way. Compared to past methods, these innovations can help any construction manager resolve busted or problematic pipelining in the Dallas, Texas area.

Low-Risk Repairs for A Construction Manager

While proven to work, CIPP installation methods need expertise behind them. Contractor mistakes can lead to bigger problems, so you need to hire the right people. For example, generating the pressure necessary for inversion via pressure vessels, scaffolds, or a Chip unit (a small piece of semi-conducting silicone) takes skill—not everyone can pull this off.

APR contractors can expertly cure resin and form tight-fitting, joint-less, and corrosion-resistant replacement pipes. CIPP methods include the use of hot water, UV light, or steam—all tools to fix your unfortunate scenario. Simply put, you want a company with experience like APR to ensure that everything goes exactly right. Low-risk repairs should be a goal for any construction manager.

Save on Time & Expenses with Advanced Pipe Repair

Another perk when partnering up with APR is a time-saving, less disruptive process than traditional dig-and-replace steps. When using CIPP methods, a flexible camera can inspect the damaged pipe when it’s difficult to reach.

This helps to determine where repairs need to be made without creating a large entry point. CIPP requires only a small hole to investigate. Once finished, this point is barely detectable. APR technicians will help you save time and expenses by properly doing the job.

A Construction Manager Can Benefit from Working With APR

Ultimately, if you are a construction manager for commercial properties, then partnering with CIPP in Dallas and APR offers you quality pipe repair and realignment. APR’s CIPP contractors can address any commercial, industrial, or municipal sewer system in the Dallas area. It’s our promise that your pipes will be fixed in a convenient and speedy manner. Contact us today.