CIPP is a modern innovation in pipeline rehabilitation. But is this technology a new development, or has it been around for a while? The answer is fascinating and complex, as the history of CIPP spans decades of experimentation, innovation, and engineering breakthroughs.

From early experiments to cutting-edge techniques, CIPP development has been a journey of discovery and ingenuity, driven by a commitment to improving infrastructure and protecting the environment.

Read on as we dive into the history of CIPP and uncover the remarkable history of this transformative technology.

The History of CIPP

In 1971, British engineer Eric Wood developed the first CIPP method for rehabilitating small-diameter water mains. The process involved using a resin-saturated felt liner, which technicians inserted into the old pipe and cured with hot water or steam to create a new line. The method quickly gained popularity due to its cost-effectiveness and minimal disruption to surface infrastructure.

In the 1970s, contractors adopted the method for sewer pipes in the United States. Their process involved inserting a liner into the existing pipe and inverting it using water or air pressure, effectively turning the liner inside out. Once the liner was in place, they used hot water or steam to cure the resin, creating a new, seamless pipe.

In the 1980s, experts further refined the technology by introducing polyester resin liners. These new liners were lighter and more flexible than their fiberglass alternatives, making them easier to install in complex layouts and bend pipes. Finally, in the 1990s, ultraviolet light began to cure the resin. It allowed faster curing times, reduced costs, and improved quality control over the curing process.

CIPP technology continues to advance and expand with new materials, methods, and equipment to meet the growing demand for pipeline rehabilitation.

Advancements in CIPP Technology

Underground pipeline rehabilitation has come a long way since the days of traditional dig-and-replace methods that required extensive excavation and disruption. Since its inception, CIPP has consistently revolutionized the field of pipeline rehabilitation. Some advancements in CIPP include:

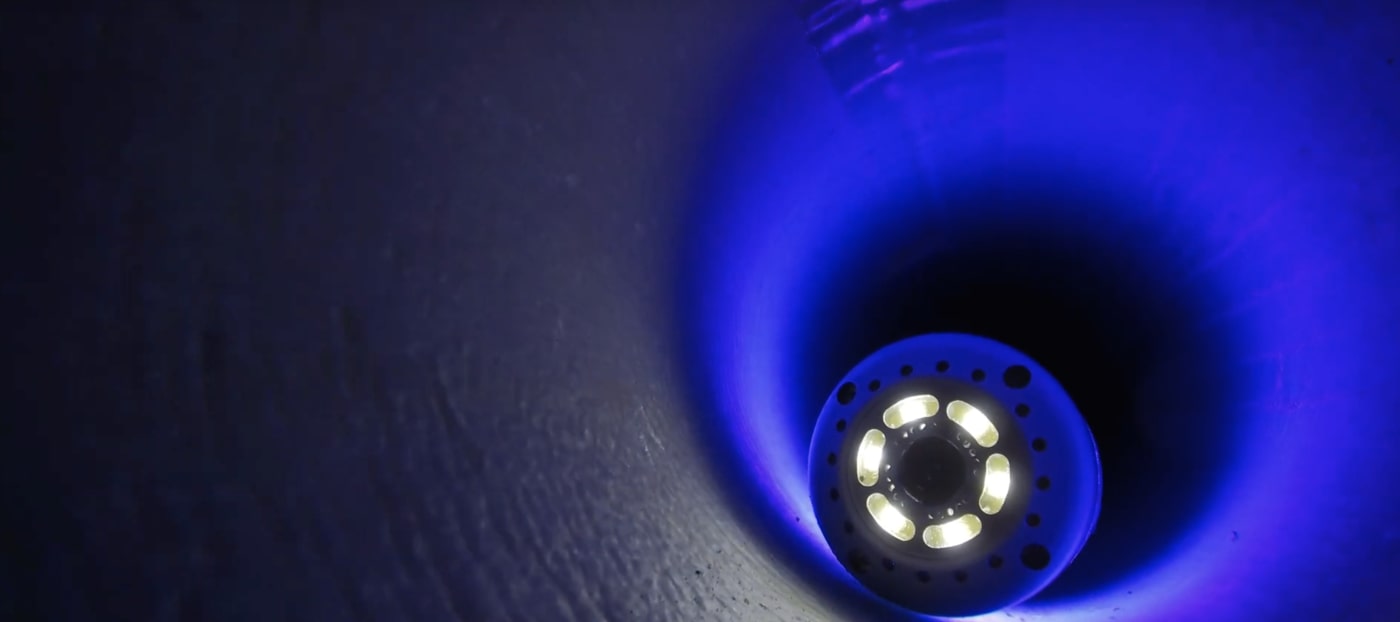

UV-Cured Liners

UV-cured liners improve the curing process by using ultraviolet light to cure the resin instead of hot water or steam. It results in a faster repair with less downtime, and it is environmentally friendly.

Lateral Lining

Lateral lining is a technique that facilitates the trenchless repair of lateral connections between pipes. It involves inserting a liner into the main pipe and extending it into the lateral connection, effectively creating a new pipe within the old one.

CIPP Liners with Enhanced Properties

CIPP has adapted new materials, such as Kevlar and carbon fibers, to enhance the liners’ tensile strength and impact resistance. These materials create liners that are more resistant to root intrusion, corrosion, and wear.

If you’re tired of dealing with messy, expensive, and time-consuming trenching methods, it’s time to consider CIPP. Thanks to pipe relining, pipe maintenance has never been easier. Why wait? Contact Advanced Pipe Repair, and let us help you determine the right trenchless method!