Understanding pipe lining cost per foot large-diameter applications requires looking beyond just a single number. Unlike smaller residential projects, large-diameter pipe lining is typically used for municipal, industrial, and utility infrastructure. In these areas, pipe size, access constraints, and operating conditions can vary widely. As a result, pricing is influenced by a range of technical and logistical factors. Each project must be evaluated on an individual basis for accurate pricing.

This guide breaks down the major cost drivers, typical price ranges by lining method, common project add-ons, and how trenchless rehabilitation compares to full pipe replacement from a long-term financial perspective.

Key Cost Factors That Influence Pipe Lining Cost per Foot Large-Diameter Application

Large-diameter pipe lining projects are complex, and costs are shaped by several interrelated variables. Understanding these factors helps municipalities and facility owners build more accurate budgets and timelines.

Pipe Diameter

Diameter is one of the most significant cost drivers. As pipe size increases, material volume, equipment requirements, and installation time also increase. Larger pipes often require:

- Specialized liner materials

- Larger curing or placement equipment

- Additional crew coordination

- Longer installation windows

A 24-inch pipe and a 96-inch pipe may both be considered “large-diameter,” but their lining costs can differ substantially.

Access Points and Site Conditions

Access conditions play a major role in determining overall cost. Pipes located beneath roadways, rail lines, waterways, or dense urban environments may require additional planning and setup.

Limited or poorly positioned access points can lead to:

- Additional excavation for entry and exit pits

- Extended setup and mobilization time

- More complex traffic control or site management

Projects with existing manholes or open access points are generally more cost-efficient.

Pipe Condition and Structural Integrity

The existing condition of the pipe directly impacts the lining method selection and preparation requirements. Pipes with heavy corrosion, deformation, or joint failure may require extensive cleaning or structural reinforcement before lining can proceed.

Factors such as cracks, ovality, infiltration, or material loss can increase preparation time and affect method choice, influencing total cost.

Average Cost Ranges per Foot by Lining Method

Large-diameter pipe lining costs vary significantly depending on the rehabilitation method used. Below are general industry ranges intended for planning purposes. Actual pricing depends on site-specific conditions.

Cured-In-Place Pipe (CIPP)

CIPP is commonly used for large-diameter gravity pipes and offers a fully structural liner.

Typical cost range:

-

$200 to $600+ per linear foot

CIPP costs increase with diameter, liner thickness, resin type, and curing method (steam, hot water, or UV). It is often selected for its structural strength and long service life.

Cementitious Lining

Cementitious lining is frequently used for water and wastewater pipes where corrosion protection and hydraulic improvement are primary goals.

Typical cost range:

-

$100 to $300 per linear foot

This method is generally more cost-effective for large-diameter pipes, but it is not always suitable when full structural rehabilitation is required.

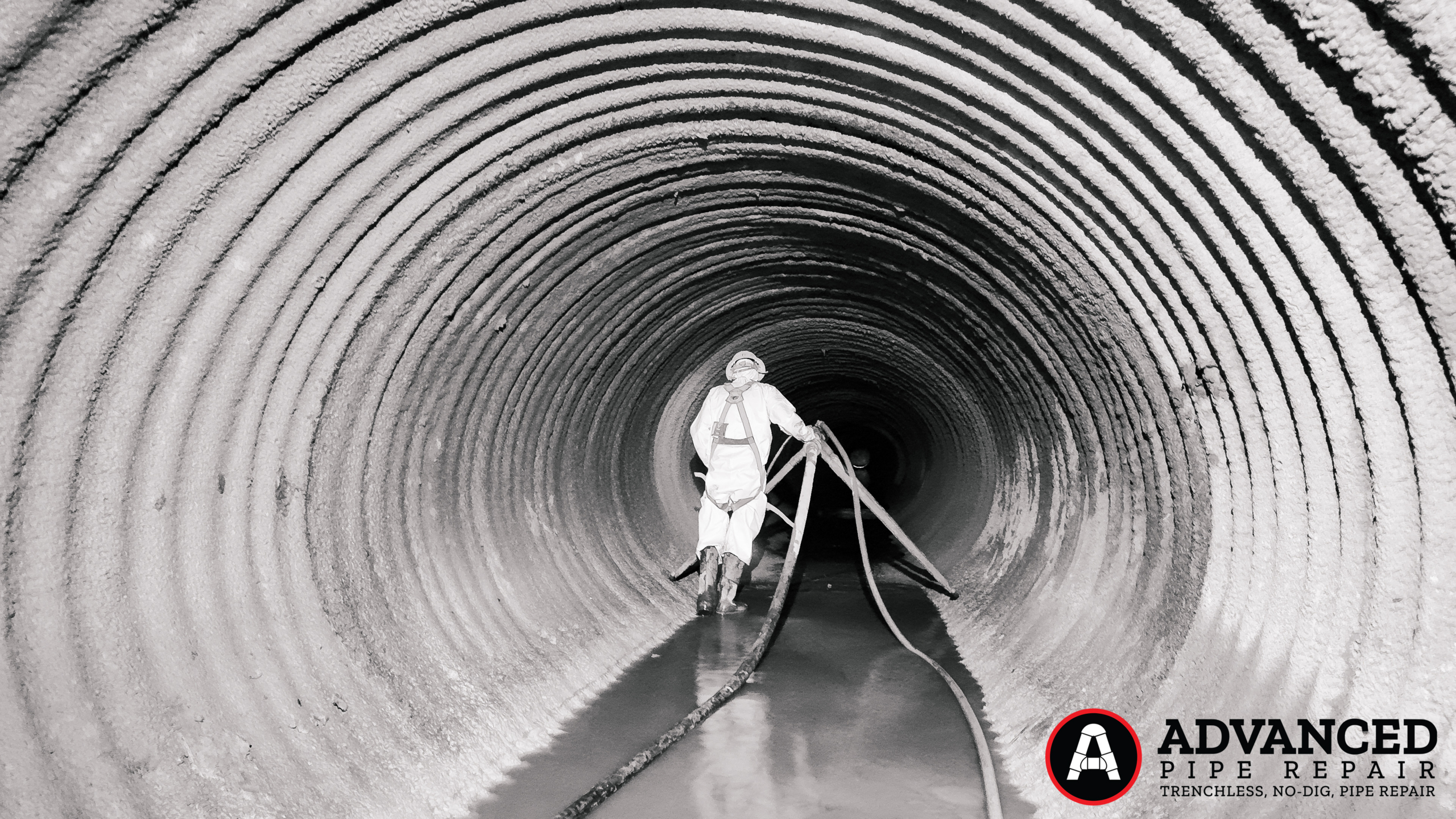

Shotcrete or Spray-Application Liners

Shotcrete and other spray-application systems are often best for very large pipes, culverts, and tunnels.

Typical cost range:

-

$250 to $700+ per linear foot

These systems can accommodate irregular shapes and severe deterioration but may involve longer curing times and more extensive surface preparation.

Common Project Add-Ons That Affect Total Cost

In addition to the lining itself, most large-diameter pipe projects require supplemental services that contribute to overall cost.

Pipe Cleaning and Surface Preparation

Before lining, pipes typically require mechanical or hydraulic cleaning to remove debris, scale, roots, or corrosion. Heavy buildup or structural obstructions can increase cleaning time and cost.

CCTV Inspection and Documentation

Pre- and post-lining CCTV inspections are standard practice for quality control and documentation. These inspections verify pipe condition, confirm liner installation, and provide records for asset management.

Flow Bypass and Temporary Pumping

Active sewer or stormwater lines often require bypass pumping to maintain service during installation. Bypass systems can range from simple setups to complex multi-pump configurations depending on flow volume and site constraints.

Each of these add-ons should be part of what you consider during early budgeting, as they can represent a meaningful portion of total project cost.

Long-Term Cost Comparison: Lining vs. Full Replacement

While trenchless pipe lining may appear costly upfront, it often delivers significant long-term savings compared to open-cut replacement.

Key financial advantages of lining include:

- Avoidance of roadway excavation and restoration

- Reduced labor and equipment costs

- Shorter project timelines

- Minimal disruption to traffic and surrounding infrastructure

- Extended service life of existing assets

In many cases, pipe lining allows municipalities to rehabilitate aging infrastructure while deferring or eliminating the need for full replacement, resulting in lower lifecycle costs.

Get Pipe Lining Cost per Foot Large-Diameter Estimates with Us

Estimating pipe lining cost per foot large-diameter applications requires a detailed evaluation of pipe size, condition, access, and rehabilitation method. While per-foot pricing ranges provide helpful benchmarks, accurate project costs are more accurate through professional assessment and site-specific analysis.

For municipalities and facility owners evaluating large-diameter pipe lining options, Advanced Pipe Repair provides trenchless rehabilitation solutions designed for complex infrastructure projects. Their team offers large-diameter pipe lining services and can assist with inspections, method selection, and detailed cost estimates.

Contact Advanced Pipe Repair today to schedule an evaluation and receive a project-specific estimate tailored to your system and budget.